Ligentec’s photonics ambitions grow beyond silicon nitride

Ligentec, the Swiss-French photonics foundry spun out of EPFL in 2016, is entering a new phase. Long known for its low-loss silicon nitride waveguides, the company is now positioning itself as a full-stack photonic integration platform. According to co-founder Michael Geiselmann, Ligentec is expanding well beyond its passive roots, adding high-speed modulators, detectors and lasers to its offering.

“The market still sees us primarily as a silicon nitride company, but that’s only half the story now,” Geiselmann says. “The real shift is in heterogeneous integration. We’re combining low-loss waveguides with active components to deliver complete functionality on a chip.”

Self-financed

Ligentec’s technology was born out of the lab of professor Tobias Kippenberg at EPFL. Originally focused on nonlinear optics for applications like frequency combs and supercontinuum generation, the company quickly saw broader demand. Today, Ligentec’s light-based chips serve quantum, sensing and telecom markets, with customers ranging from metrology firms to lidar developers.

Ligentec’s edge lies in a structural choice: its single-layer waveguide design confines light more tightly than stacks employed by competitors. This enables more compact chip layouts and lower losses in curved waveguides, Geiselmann explains. “In applications where you need long delay lines or tight spirals, like quantum or lidar, our platform has clear advantages. You can pack ten meters of waveguide into a tiny footprint.”

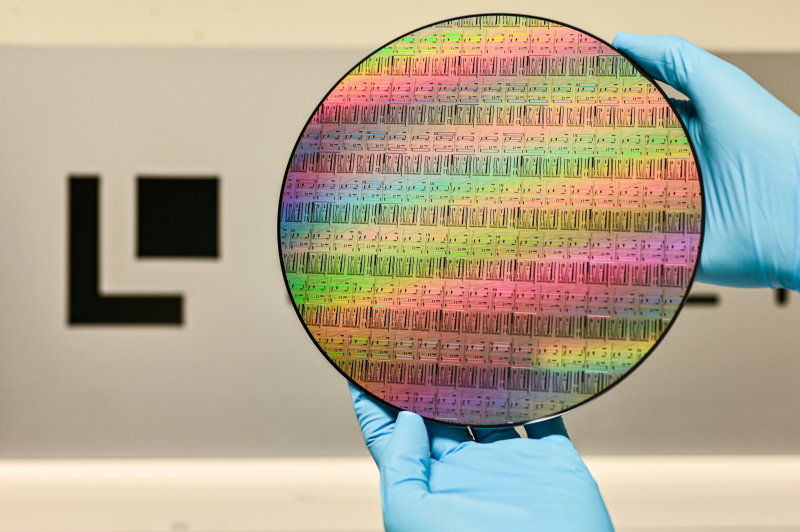

Since 2020, Ligentec has produced its chips through a partnership with X-Fab, a foundry with sites in France, Germany, Malaysia and the US. The process runs on 200-millimeter wafers using CMOS-compatible tools, which was part of the strategy from day one. “From the start, our vision was to take the platform from lab to fab. The processes we developed in the university cleanroom were purposefully chosen to match those in a commercial fab.”

Today, Ligentec employs more than 80 people and has grown its business at a 50 percent annual rate on average. Remarkably, the company has done this without venture capital. “We’re fully self-financed. If the market grows, we grow.”

Full functionality

Ligentec groups its business into three main verticals: optical computing, connectivity and sensing. Each currently contributes roughly equally to revenue, although computing is showing the fastest growth. Within these segments, the use cases are broad, ranging from biosensing to quantum key distribution.

Ligentec finds itself in an increasingly complex landscape, which integrated-photonics accelerator Photondelta is looking to bring together to launch a new high-tech industry. Geiselmann is a strong believer in that mission. “I think that Europe can be a one-stop shop for photonics needs. We already have very strong offerings as well as very good universities, especially in the Benelux, and very good research and technology organizations doing groundbreaking work. If we collaborate, we can go far indeed. That’s where an organization like Photondelta brings real value, by fostering this collaboration and ensuring we build on what we have to close the gaps in the supply chain.”

That said, Geiselmann warns against too much localization. “Every local government wants its own thing, but we need a unified European offering. We don’t need an integrated-photonics fab in every country. Instead of duplicating what already exists, we should build on it and close the gaps in the supply chain. Invest in what’s next, not in what’s already covered.”

While larger players like Globalfoundries have entered the silicon nitride space, Geiselmann believes Ligentec’s model remains competitive. “They operate at 300 millimeters, which requires high volumes and drives up cost,” he says. “Our 200-millimeter platform hits a sweet spot: it provides world-class performance, it’s flexible, cost-efficient and perfectly suited for emerging applications.”

Looking ahead, Ligentec is doubling down on heterogeneous integration. The company is already adding lithium niobate modulators and III-V detectors and lasers to its chips, and plans to scale these offerings from R&D to volume production over the next few years. As these technologies continue to mature, Ligentec wants to be seen not just as a materials supplier but as a key enabler of complete photonic systems. “We deliver full photonic functionality, integrated and ready to scale.”

This article was written in close collaboration with Photondelta. Top image credit: Ligentec