Your cart is currently empty!

Kalpana brings “superspatial ALD” to the packaging industry

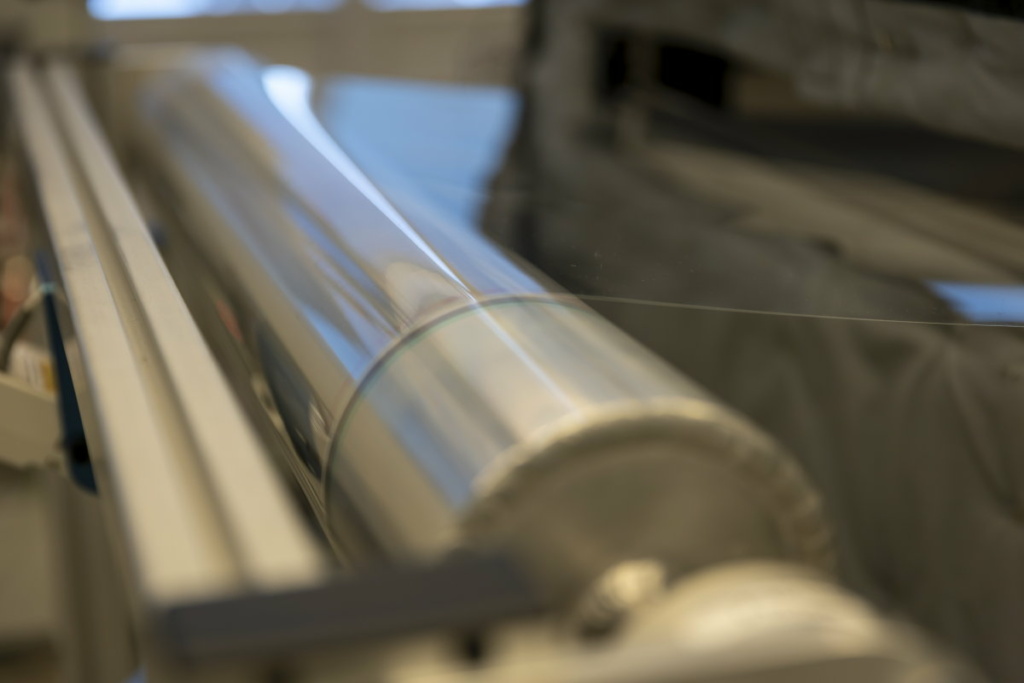

With “superspatial ALD” technology, Delft-based Kalpana Systems developed a compact roll-to-roll machine that deposits moisture- and oxygen-resistant barrier layers on flexible substrates. With this new form of ALD, the startup targets the markets of flexible OLED displays and solar cells and takes its first steps toward the packaging industry.

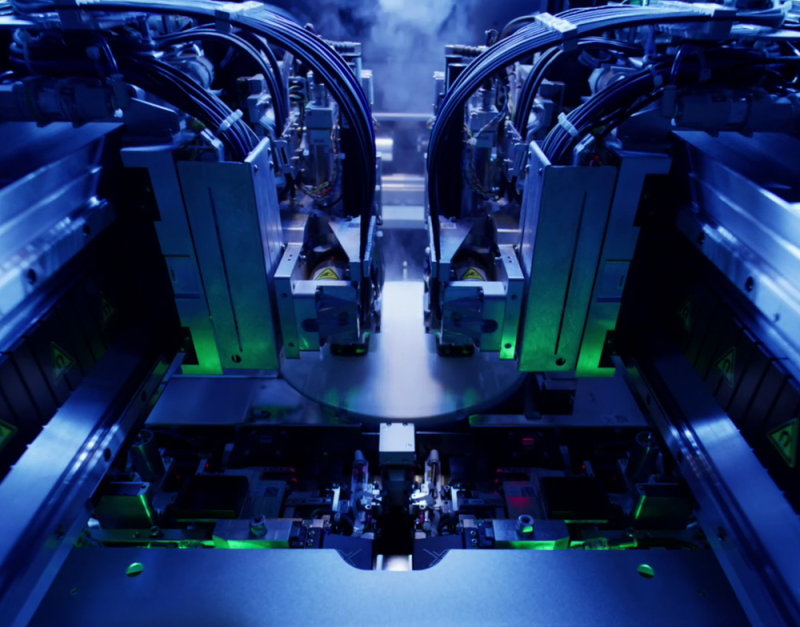

A spiral-shaped conveyor system, a rotating deposition head and extremely precise gas control. With these core elements, Kalpana Systems, founded in 2021, aims to transform the traditional batch-based atomic layer deposition (ALD) process into a high-throughput method for flexible substrates. Its roll-to-roll machine applies moisture-resistant metal oxide barriers to these substrates, for example for flexible OLED displays and solar cells.

The machine is designed for integration into existing roll-to-roll production lines. Thanks to a compact design, precise gas separation and high throughput, Kalpana makes ALD attractive for sectors beyond electronics where large-scale production at the lowest possible cost is essential. Because the machine is compatible with flexible substrates and ALD layers are wafer-thin, which makes them insignificant in recycling, the packaging industry is an interesting market for the Delft-based company. This sector manufactures and reuses billions of kilometers of material annually.