Switching drive laser technology could improve EUV source power efficiency by a factor of ten. A project in the US will investigate.

EUV lithography is pretty energy-intensive. Operating a single EUV scanner requires up to 10.2 gigawatt hours per year, according to tech consultancy Techinsights. That’s equivalent to the annual energy requirements of a small town. Consumption will run up to 12.2 gigawatt hours per tool annually for high-NA systems. Although EUV comprises only 10 percent of fab electricity consumption, those numbers need to come down if the semiconductor industry is to make good on its commitment to drastically lower carbon emissions even as the adoption of EUV increases. ASML expects customer spending on EUV tools to grow with a double-digit CAGR between 2025 and 2030.

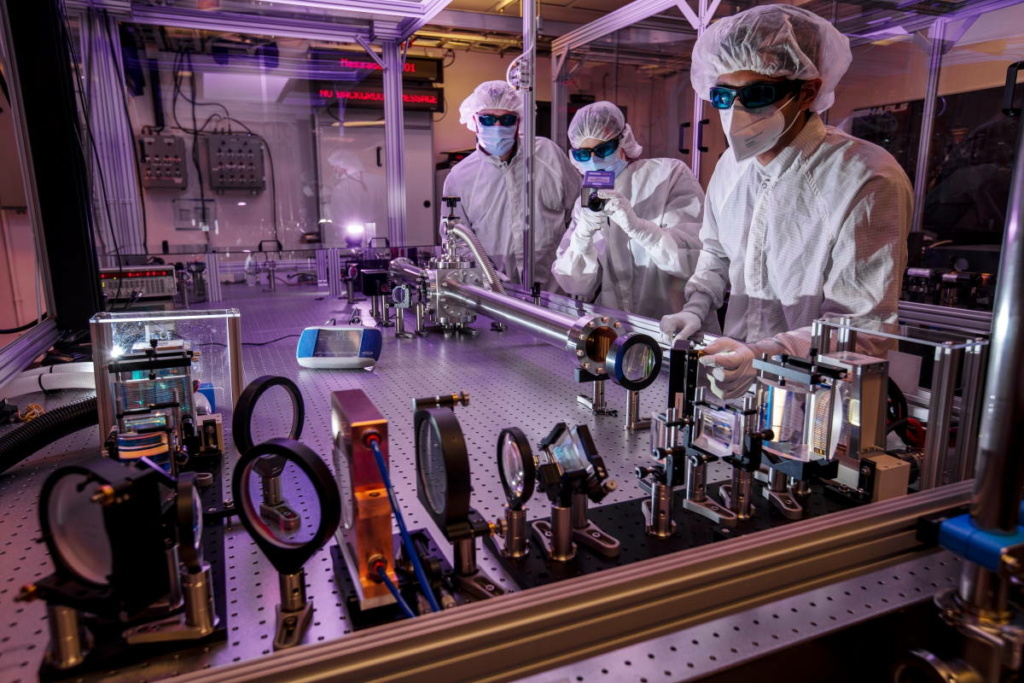

An obvious target for saving energy is the EUV source: only a fraction of the input energy is converted into EUV light. Although ASML and its partners have managed to increase efficiency over the years, there may be room for improvement. A 4-year, 12-million-dollar project led by the Lawrence Livermore National Laboratory (LLNL) will put a new type of drive laser to the test. If successful, EUV source efficiency could increase about ten times.