Your cart is currently empty!

Behind the bearing: using advanced software to simulate real-life working conditions

SKF, an industry leader in bearing design and manufacturing, is working with consultants from Alten to build software tools that transform how one of engineering’s most used and crucial components is designed, tested and maintained.

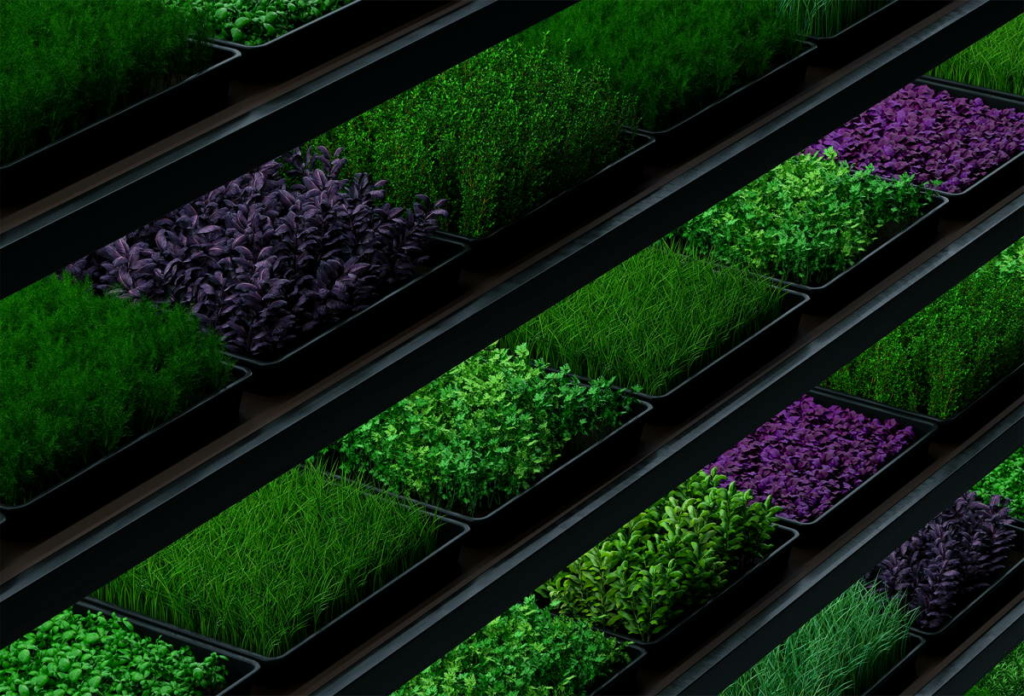

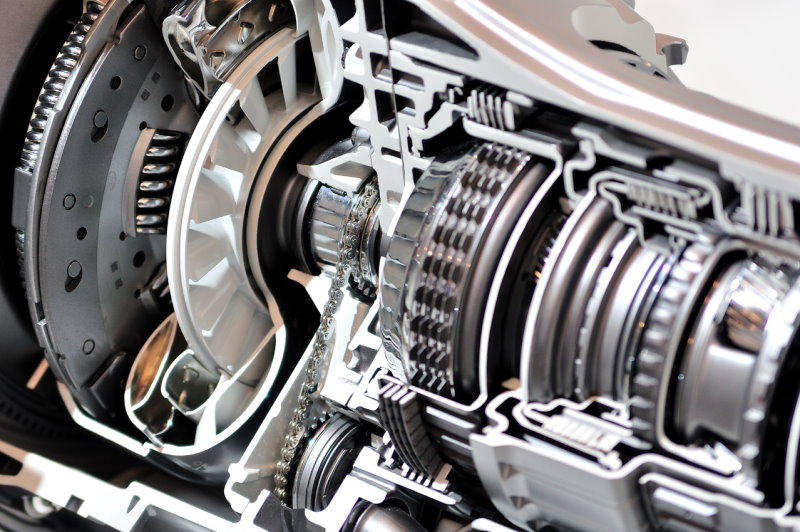

In the vast and intricate world of engineering, SKF bearings play a crucial role, serving as the silent workhorses that facilitate smooth and efficient motion in countless machines and devices. From the simplest household appliances like washing machines, refrigerators and vacuum cleaners to highly sophisticated machinery including MRI machines, wind turbines, jet engines and the rovers that traverse the terrains on Mars, bearings are the very fundamental units that define rotation.

With bearings running at the heart of such complex systems, bearing malfunctions not only impact safety and productivity but also lead to significant additional maintenance costs. For instance, when a jet engine stops rotating due to a bearing failure, the entire unit must be dismantled to replace the faulty component. To avoid these undesirable circumstances, it becomes imperative to design bearings that can withstand a wide range of operating conditions. The only way to reliably perform this action in a fast and repeatable manner is by using robust simulation tools. Undertaking factory durability tests on every component is not only cumbersome and expensive but also environmentally unfriendly. Additionally, re-manufacturing a 5-ton wind turbine bearing to test every slight change isn’t trivial.

Alten consultants develop and maintain simulation software that assists SKF engineers and their numerous clients in designing bearings and bearing systems with various geometric configurations tailored to specific use cases. These tools allow them to meticulously simulate performance under a wide range of operating conditions. Two such simulation software programs are Noise-and-Vibration-Analysis and SKF Simpro. The former helps in designing and detecting bearing failures from a vibroacoustic standpoint; the latter focuses on bearing selection and designing bearing systems while catering to specific geometric constraints, taking into account the dynamics of roller bearings and mechanical systems.

Noise-and-Vibration-Analysis

In the design of products with rotating parts, noise and vibration characteristics are high-priority aspects. Roller bearings, due to their relatively low energy dissipation, are among the most used machine elements in rotating products. They transfer high forces and heavy loads, significantly influencing a machine’s vibration and acoustical behavior. This impact manifests in unwanted noise, which can cause discomfort and pose serious health hazards. Additionally, the rotation of bearings can be a source of vibrations that lead to mass imbalances and potential structural failure of machines.

Mechanical resonance disasters vividly demonstrate the power of vibrations. Mechanical resonance is the tendency of a system to oscillate at greater amplitude when its natural frequency matches the frequency of external vibrations. This can cause violent swaying motions and catastrophic failures in improperly constructed structures, such as bridges, buildings and airplanes. A less frightening example is an opera singer breaking a glass with their voice.

The Noise-and-Vibration-Analysis software is an internal SKF tool that assists engineers in designing and maintaining bearings to tackle these problems. For instance, the noise generated from a bearing in a wind turbine contains information that’s indiscernible to the human ear. However, the software employs sophisticated signal processing and vibroacoustic algorithms to decode this audio, detecting surface defects, dirt in the bearing, shaft misalignments, mounting problems, mass imbalances and critical speeds of the rotation system. Additionally, it helps engineers design new bearing systems by numerically modeling, simulating and predicting these issues under various operating conditions.

The workflow begins with a sensor that detects vibration and acoustic signals from a vibrating surface. Vibration signals are collected using devices such as accelerometers, displacement sensors and vibrometers, while acoustic signals are gathered using condenser microphones. These devices record sound and vibration as a continuous-time signal, but since postprocessing is typically done with discrete (digital) data, the original signal must be discretized before further processing.

The software then converts this time signal from the time domain (function of time) into the frequency domain (function of frequencies), representing it as a sum of sinusoids, each with its own phase and amplitude. Each sinusoid’s phase and amplitude can be expressed by a single complex value, allowing the frequency domain to consist of one complex value for each frequency component.

For analyzing signals from rotating machinery, frequency domain analysis offers clear advantages. Machinery vibrations typically originate from multiple rotating components operating at different frequencies, such as the rotational shaft frequency and the gear tooth-meshing frequency. In the frequency spectrum, each component can be easily identified. The software decodes both time domain and frequency domain data to pinpoint defects, misalignments, waviness, critical speeds and contamination.

SKF Simpro

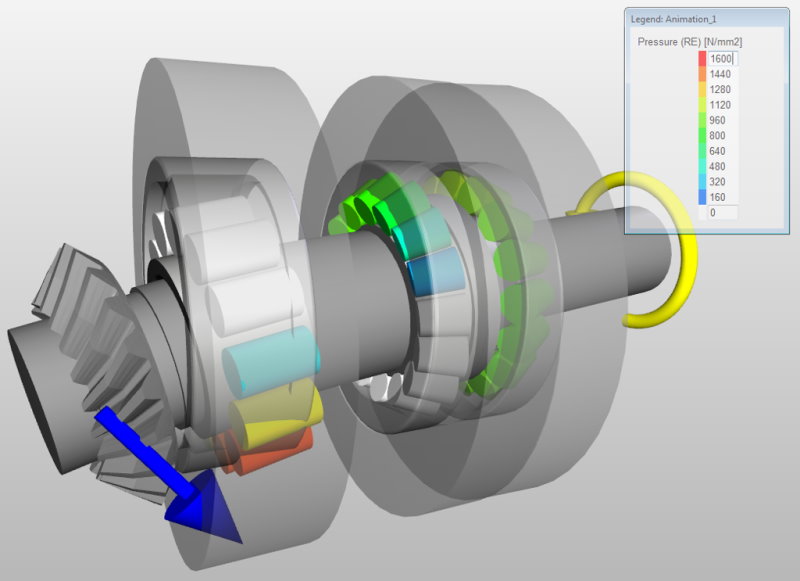

While Noise-and-Vibration-Analysis focuses on detecting and diagnosing bearing failures through acoustic and vibration signals, the SKF Simpro software makes it possible to exhaustively simulate bearing performance under a wide array of operating conditions with a much broader scope. SKF Simpro provides engineers with a comprehensive tool to predict and optimize bearing behavior through detailed modeling and virtual testing, ensuring reliability and efficiency in various applications. It’s designed to simulate a broad range of bearing parameters and service conditions, such as misalignment, load and moment, friction, raceway contact stresses, fatigue life and lubrication. By creating detailed models that account for variables like temperature, speed, lubrication type, contamination levels and material properties, it enables engineers to predict how bearings will perform in real-world applications.

The need for such advanced simulation tools arises from the complexities involved in bearing design. Bearings operate in diverse environments and are subject to various forces and stresses. Traditional methods of testing each component under factory conditions are cumbersome, expensive and environmentally unfriendly. This is where SKF Simpro becomes invaluable, offering a virtual design environment to exhaustively simulate bearing performance, thereby reducing the need for physical prototypes and enabling rapid iteration and optimization.

The tool’s capabilities also extend to components like shafts, seals, housings, gears and bolts. It can simulate the flexibility of shafts, bearing rings and housings, as well as thermal effects, bolt preloading and mounting conditions. This allows for comprehensive simulations, including quasi-static, modal, transient, parametric, load cycle and DOE (design of experiments) studies.

From a postprocessing perspective, SKF Simpro offers extensive capabilities. Engineers can plot any parameter in charts, assemble detailed reports and create animations of the resulting movements. This visual representation helps in understanding the complex interactions within the bearing system and aids in making informed design decisions.

SKF Simpro’s simulations are grounded in fundamental physics, using governing equations from solid mechanics, tribology, thermodynamics and heat transfer. In solid mechanics, the tool models the stresses and strains within the bearing materials, predicting how they deform under various loads. Tribology, the study of friction, lubrication and wear, is crucial in understanding the contact interactions within the bearings. SKF Simpro evaluates the lubrication regime, calculating film thickness and frictional forces to optimize bearing life and efficiency. Thermodynamics and heat transfer simulations predict temperature distributions within the bearing, ensuring that the thermal environment doesn’t adversely affect performance. Additionally, material science and metallurgy are integrated into the software, allowing for the selection and evaluation of different materials based on their mechanical properties, wear resistance and fatigue life.

By incorporating these advanced physics models, SKF Simpro provides a thorough analysis of bearing performance under realistic operating conditions. This comprehensive approach ensures that bearings are designed not only to meet but exceed the rigorous demands of modern machinery.

Reliability, efficiency and longevity

Advanced software tools such as Noise-and-Vibration-Analysis and SKF Simpro, developed over decades by multidisciplinary experts in collaboration with software developers from Alten, revolutionize the way bearings are designed, tested and maintained. They enable engineers to simulate real-life working conditions, predict performance and detect potential defects early through sophisticated signal processing and numerical modeling techniques.

By harnessing the power of these software solutions, SKF continues to enhance the reliability, efficiency and longevity of its bearings, ensuring that they can withstand the demanding environments of various applications. This technological advancement not only improves safety and reduces maintenance costs but also fosters innovation and sustainability in bearing design and manufacturing.