Atlas Copco is implementing digital twin technology to drive digital transformation, particularly in its Compressor Technique division. With more than 250,000 connected machines in the field, the global industrial company is building a digital ecosystem with real-time data acquisition that supports data-driven decision-making, operational efficiency, product personalization and increased customer value.

Digital twins at Atlas Copco transcend traditional simulation models. They’re dynamic, high-fidelity digital replicas of physical products, encompassing data from design, production, operation and service phases. Developed using Matlab and Simulink, digital twins model the interactions between physical systems, sensors and controllers, enabling accurate replication of real-world scenarios and efficient testing that overcomes limitations of traditional testing approaches.

Atlas Copco’s digital twins create a single source of truth by processing millions of real-time data points from production, testing and design systems, unifying the entire value chain – from design to service. As a result, the company drives continuous improvement through evidence-based and data-driven decision-making.

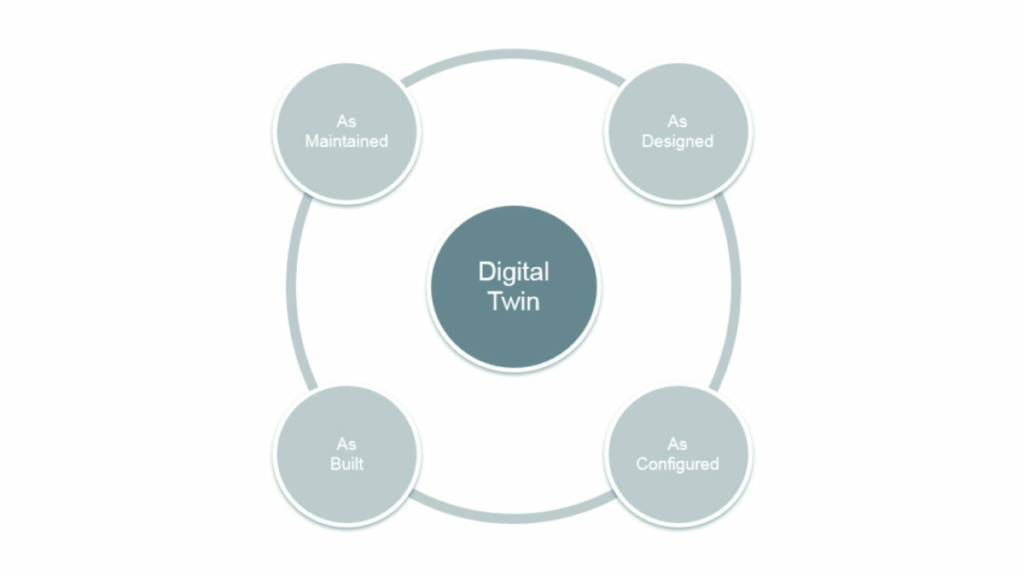

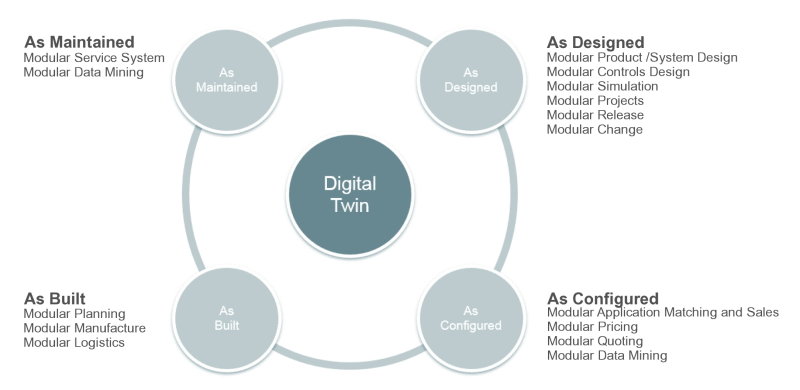

The digital twin framework for compressors at Atlas Copco comprises four key phases: as designed (centered on prototyping and feasibility analysis), as configured (tailoring products to match exact customer requirements), as built (capturing production data and ensuring traceability) and as maintained (using operational data for predictive maintenance and continuous improvement). Each of these stages contributes to a full-circle approach, ensuring continuity from ideation to designing and building compressors to their operation. The digital twin becomes a living, evolving resource that informs decision-making at every level.

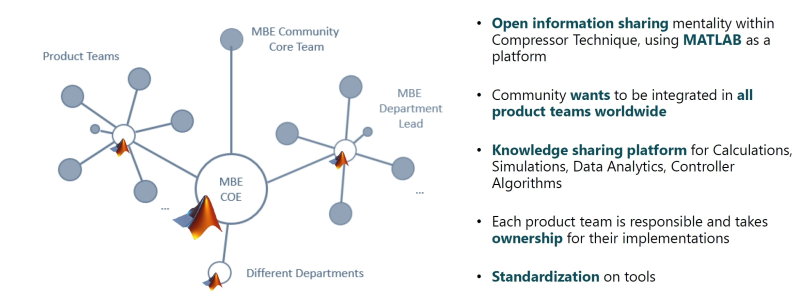

To enable the digital twin strategy, Atlas Copco established the Model-Based Engineering (MBE) Community of Excellence, a global network that connects teams across departments and divisions. This community leverages model-based design (MBD) principles for knowledge-sharing, standardization and collaboration. It plays a crucial role in aligning design, configuration, build and maintenance efforts, ensuring that lessons learned in one area are rapidly disseminated throughout the organization.

A key challenge is balancing model fidelity with development efficiency, accurately capturing the dynamic behavior of the product for control algorithm design without wasting development time and computational resources. It’s a balancing act between simulation precision and performance, one that Atlas Copco continually refines through testing, collaboration and data. The GA VSDs OIS line of variable-speed-drive compressors exemplifies this approach as the first product designed entirely with digital twin technology, enabling optimized control algorithms, CI/CD workflows, more efficient operation and services like predictive maintenance.

Infrastructure for digital twins

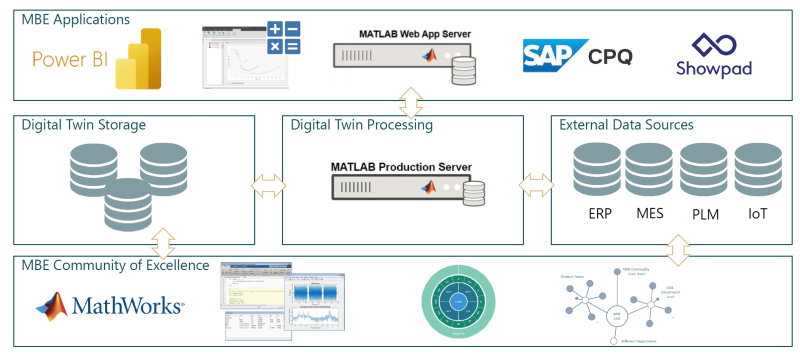

A robust and scalable MBE platform forms the operational backbone of Atlas Copco’s digital twin ecosystem. Central to this is the Matlab Production Server (MPS), which bridges operational technology (OT) and information technology (IT) systems. The platform links physical systems, digital models and enterprise software tools, enabling engineers, marketing analysts and service managers to access and interact with the same datasets and insights. MPS also allows engineering teams to share models and applications with non-Matlab users, accelerating development and collaboration.

The MBE platform offers three core functionalities. First, it provides centralized processing: MPS centrally runs models, ensuring security, consistency, scalability and low-latency processing of deployed code. The second core functionality is API-based integration: the platform connects with tools such as Power BI, SAP, Matlab Web App Server and many other applications, making it easy to bridge the gap between OT and IT. The third is cloud scalability: cloud infrastructure allows dynamic scaling to meet processing demands, from overnight model testing to global web applications.

The MBE infrastructure has evolved by layering on existing components and integrating systems such as PLM, ERP, IoT and test data. Digital twins are centrally deployed and accessible to relevant teams, enabling cross-functional insights. By connecting data silos, teams and tools, it’s scaled digital twins into an enterprise-wide solution, delivering benefits such as improved visibility, automation and performance optimization across all product lifecycle stages.

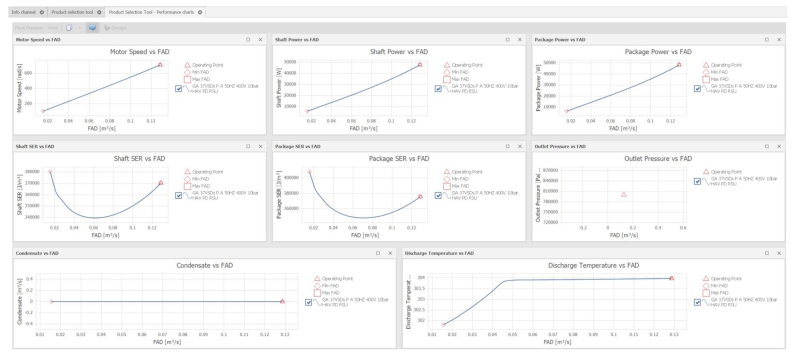

The “as configured” digital twin streamlines the sales process by providing technically sound and validated recommendations. These are based on rapid simulation of compressor performance for specific customer requirements, such as altitude, ambient temperature, humidity and usage patterns.

In the “as built” phase, digital twins bridge the gap between production lines and quality systems. Atlas Copco integrates machine tool data, measurement systems and test validations into a unified quality framework. Data from sensors, machines and operators is linked to the digital model of each unit, ensuring complete traceability. In-house engineering of all key compressor components enables the underlying digital fingerprinting, supporting root cause analysis, production optimization and regulatory compliance.

The “as maintained” digital twin enables predictive maintenance by analyzing telemetry data from more than 250,000 connected machines. The Smartlink platform processes real-world usage patterns, detects anomalies and recommends interventions. By integrating Smartlink data with engineering and production records, the system enables full traceability and root cause analysis of machine behaviors in the field. This holistic approach allows compressors to proactively alert service teams to emerging issues, minimizing downtime, extending equipment lifespan and enhancing operational reliability.

Beyond the product

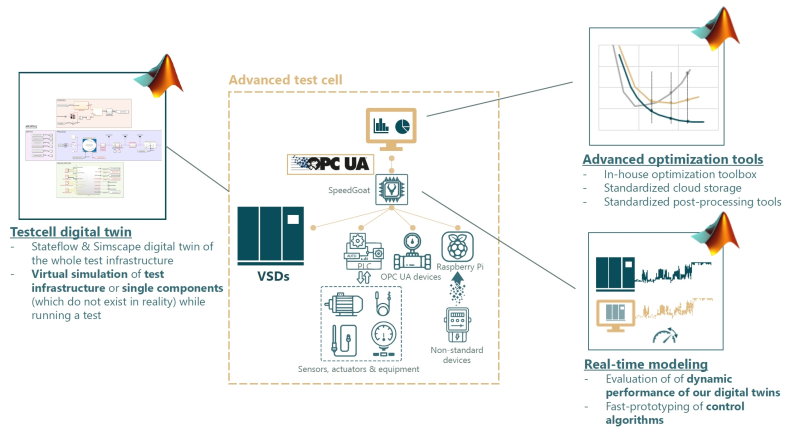

Atlas Copco’s digital twin strategy extends beyond products to the systems used for testing and validation. Advanced test cells provide an environment for real-time modeling, simulation and algorithm prototyping and testing under conditions closely resembling near-real-world scenarios. Each test cell is equipped with Speedgoat controllers running Simulink- and Simscape-based digital twins in real-time. These controllers dynamically simulate complex load conditions, environmental fluctuations and machine behavior.

Beyond this, control algorithms can be deployed and tuned on the fly. With the new MBE infrastructure, software and hardware can co-evolve in an agile, iterative loop, enabling rapid prototyping of smart control features like energy-saving modes or advanced fault detection.

Unified communication protocols, such as OPC UA, centralized data storage and reusable model components ensure that insights from one product or test can be transferred to others. By preserving and organizing large-scale test data, Atlas Copco builds a valuable knowledge base for ongoing innovation. First piloted on the GA VSDs line, this approach is now scaling company-wide, embedding intelligence into both products and their development processes.

While Atlas Copco continues to advance its digital twin capabilities, several technical challenges and development goals remain. One of them is seamless integration of Matlab-based models with other programming languages and platforms, such as Python and Databricks, to improve flexibility and interoperability across teams. Another challenge is deploying digital twins on edge devices to enable live insights and predictive control. To address these challenges, Atlas Copco is developing simplified, faster versions of its high-fidelity, computationally expensive digital twins, known as surrogate models.

In addition, Atlas Copco is preparing to roll out smart test cells across all divisions. The goal is to embed real-time simulation and testing as a standard element throughout the entire product lifecycle.

The collaboration with Mathworks and the continued partnership with training, consulting and development teams remain important and aim to refine frameworks for control systems and integration of AI-driven workflows with high-fidelity modeling. Through these initiatives, Atlas Copco strives to improve cross-disciplinary collaboration, better align AI and physical modeling, and enable virtual system simulation without the need for physical prototypes. The vision is to move from data-rich environments to insight-rich ecosystems, supporting continuous improvement through digital twin technology.