Your cart is currently empty!

Bright Photonics streamlines the integrated-photonics design journey

Thanks to 15 years of design flow development, Eindhoven-based design house Bright Photonics contractually guarantees its integrated-photonics designs are error-free.

In the rapidly evolving field of integrated photonics, where enthusiasm sometimes outpaces execution, turning an idea into a commercial product can still be a bumpy ride. Eindhoven-based Bright Photonics has built its business model around this fact. Led by physicist and founder Ronald Broeke, the photonics design house aims to make the ride as comfortable and predictable as possible.

“Our job isn’t to sell photonics for its own sake,” says Broeke. “Step one is always asking: does this make sense for your application? Will it outperform alternatives in size, cost, power or stability?” This approach positions Bright as both a technical partner and a kind of reality check, discouraging unnecessary or ill-conceived ventures into photonics. “If a photonic solution isn’t the best fit, we’ll tell.”

But when photonics is the right choice, Bright uniquely ensures that a design will turn into a working chip. No more nasty surprises, wasting tens of thousands of euros on a failed production run, because the tolerances in the design software didn’t quite line up with the foundry’s manufacturing process. In a field where chip development still carries a fair share of trial and error, Bright therefore eliminates a major roadblock.

Missteps

Frustrated with commercial software that didn’t understand photonics design well enough, Bright wrote its own solution, Nazca-Design. Nazca, now also expanding into a cloud solution, checks each design for thousands of possible human and logical errors, integrates with all photonic foundries and validates designs using a test bench approach. The goal? No surprises.

“We use our software within our development process to guarantee a chip design is flawless,” Broeke explains. “It’s built around real use cases from hundreds of projects. And because we control the software, we’re able to offer contracts that guarantee delivery of chips that we can prove to be correctly designed.” This level of assurance is rather unique in photonics and represents a major step toward industrial maturity.

As such, Bright’s work contributes to strengthening the integrated-photonics ecosystem. Part of the Photondelta network, the company quietly helps companies – be it startups or major OEMs – move from concept to product. Even if some clients are design experts themselves (or have access to them), it remains hard to grasp the workings of the integrated-photonics supply chain well enough to be successful.

“Our job is to prevent missteps from the start – through higher quality control and verification of all assumptions,” says Broeke. He points out that photonics is analog, and foundries continuously evolve their processes. Bright serves as an intermediary that knows where potential pitfalls lie.

This end-to-end control also means Bright can help customers identify not only what’s possible but what’s practical. “We’re not just drawing circuits. We’re assessing risk, checking timelines, verifying claims from foundries and validating every step before anything gets fabricated,” Broeke adds.

Pipeline

Bright’s next move takes their offering even further: in-house testing at scale. This month, the company installed the first parts of a custom-built test setup, soon capable of measuring between 5,000 and 10,000 chips per project. The system is designed to be both flexible and efficient, handling everything from prototyping to small-batch production with statistical rigor.

The move addresses another one of the industry’s key bottlenecks. “There’s no flexible open access and scalable photonic test infrastructure right now,” says Broeke. “University labs are helpful but not built for volume and two or three orders of magnitude too slow. Some larger companies producing datacenter chips can test at scale, but only for their specific product, and they’re not open to other parties. So we concluded we have to build the test setup ourselves to guarantee a reliable and predictable project outcome, just as with the software.”

Crucially, this test infrastructure is integrated with Bright’s design software. Using digital twin models, the test process is planned and simulated during the design phase, making real-world validation faster, cheaper and more reliable. This is more than a lab upgrade – it’s the last piece of a tightly integrated design-to-production pipeline.

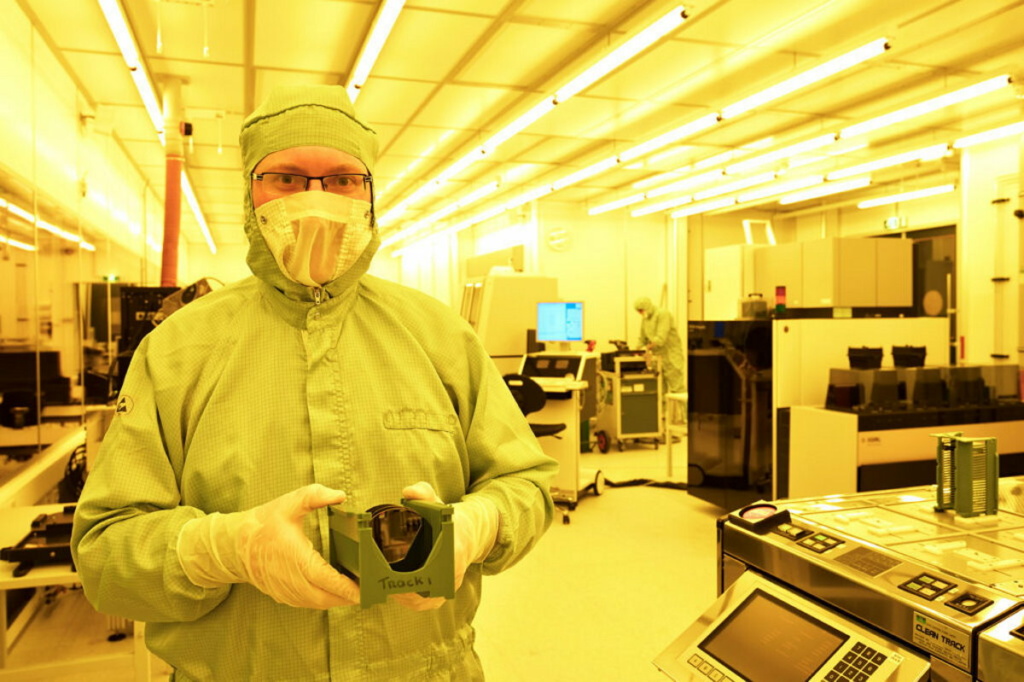

This article was written in close collaboration with Photondelta. Top image credit: Bright Photonics