Many companies are lagging when it comes to software-driven solutions and are at risk of being left behind in the industrial automation process. This is further exacerbated by the shortage of qualified specialists, especially engineers. Philipp Wallner of Mathworks explains the challenges that machine builders currently face and the pioneering solutions that leading companies must implement to remain successful in today’s economic climate.

The European machine building industry stands for precision, engineering excellence and innovative strength. However, the rules of the game are changing rapidly. Global competitors are investing in research and digital technologies, accelerating the market launch of new solutions and pursuing aggressive expansion strategies. Top quality is no longer synonymous with longer delivery times. Today, international suppliers deliver comparable quality in a shorter time, thereby meeting increased customer demands. Market leadership in the machine building industry is under pressure; a clear strategy is essential for companies to maintain their position. They must react decisively to the challenges of digitalization.

Modular architectures

The solution lies in the consistent use of modular software architectures. To remain internationally competitive, companies must invest more in the continuous development of modern and modular product and software architectures, as these form the basis for efficiently implementing future-oriented technologies and sustainably transforming development processes. In mechatronic engineering, software solutions and production systems can be adapted to different machines, production lines and processes without extensively modifying existing systems. This flexibility allows engineers to manage complex systems efficiently, accelerate product developments and quickly adapt them to changing market requirements.

The modular structure of software is becoming increasingly important in the machine building sector as customers are increasingly demanding affordable, individually tailored systems. Modular architectures enable a large variety of machines and solutions, as individual software modules can be flexibly combined and adapted. At the same time, maintainability is guaranteed, as delimited components allow targeted changes, maintenance and extensions. This allows customized customer requirements to be met efficiently without redeveloping entire systems.

The modular approach also makes it easier to integrate new technologies and functions, such as those in the field of artificial intelligence (AI). This approach enables corporate decision-makers to increase the innovative strength of their organization by optimizing cost structures, reducing time-to-market and sustainably improving their competitiveness.

Model-based workflows

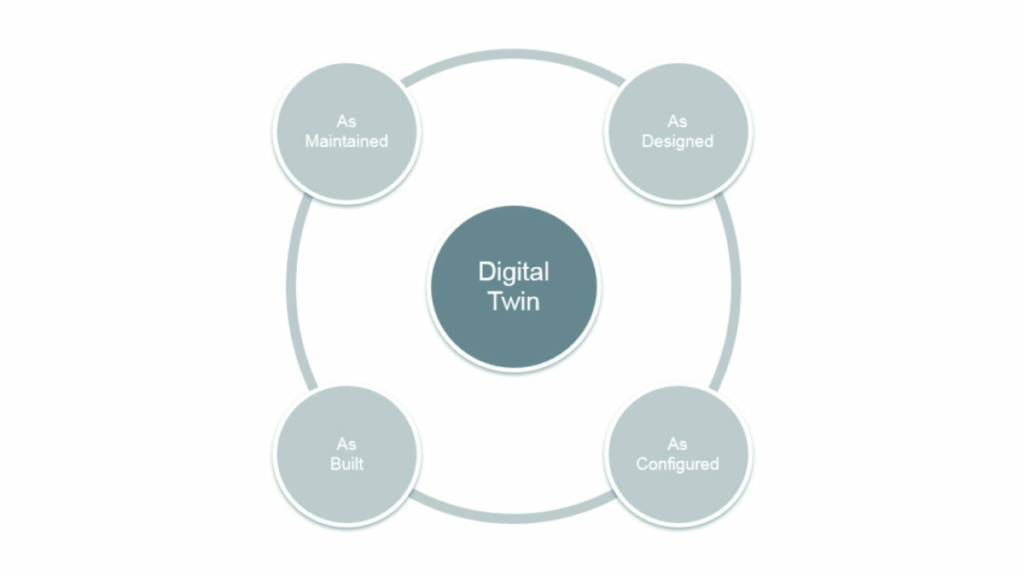

Modern mechatronic engineering processes are increasingly benefiting from digital methods and the latest software technologies. Model-based design makes it possible to virtually design, test and optimize products and systems long before physical prototypes are created. This allows risks to be identified early and accelerates the machine’s time-to-market. Models can be used as digital twins and are simulated in a realistic, virtual environment within the industrial metaverse. AI supports the process by analyzing large amounts of data, recognizing patterns, learning from the data and creating forecasts, thus facilitating well-founded decisions, automating recurring tasks and contributing to continuous process optimization. These methods shorten development cycles from hours to seconds, increase the control systems’ adaptability and efficiency, and improve product quality.

Intuitive, AI-supported development tools enable experts to contribute domain-specific knowledge to the development process and work together on creative solutions. This seamless integration of technical and software requirements considerably simplifies collaboration between engineers and software specialists. By leveraging targeted talent development and Mathworks tools like Matlab and Simulink, organizations can reduce the need for highly specialized software and AI experts and thereby secure their long-term competitiveness.

As digitalization increases, so do the cybersecurity requirements. Compliance with the Cyber Resilience Act (CRA) is becoming an integral part of product development. Companies that use model-based workflows can document, track and simulate their embedded software from the outset. This allows regulatory risks to be minimized and compliance requirements to be met efficiently and reproducibly.

Practical examples

The competitiveness of the machine building industry largely depends on consistently integrating model-based design, AI, hardware-independent code generation and digital twins into value chains. Companies that use these technologies across the board can significantly shorten development cycles, efficiently meet regulatory requirements and increase their development strength in a targeted manner. A clear roadmap is crucial: preserve existing expertise, scale it through AI and gradually transfer it into model-driven processes. Companies that act now will secure their lead over the global competition and actively shape the next era of mechatronic engineering.

Industry leaders such as Krones and Siemens Energy are already successfully implementing these approaches. At Krones, engineering teams are using Matlab to develop AI-based process control and quality monitoring solutions for production plants. Through simulation, validation and automatic code generation, AI models are efficiently applied to industrial control systems, increasing transparency and accuracy. Siemens Energy uses Matlab and Simulink to identify and resolve design and integration problems of their complex power transmission systems at an early stage – before the first physical prototypes are in operation.