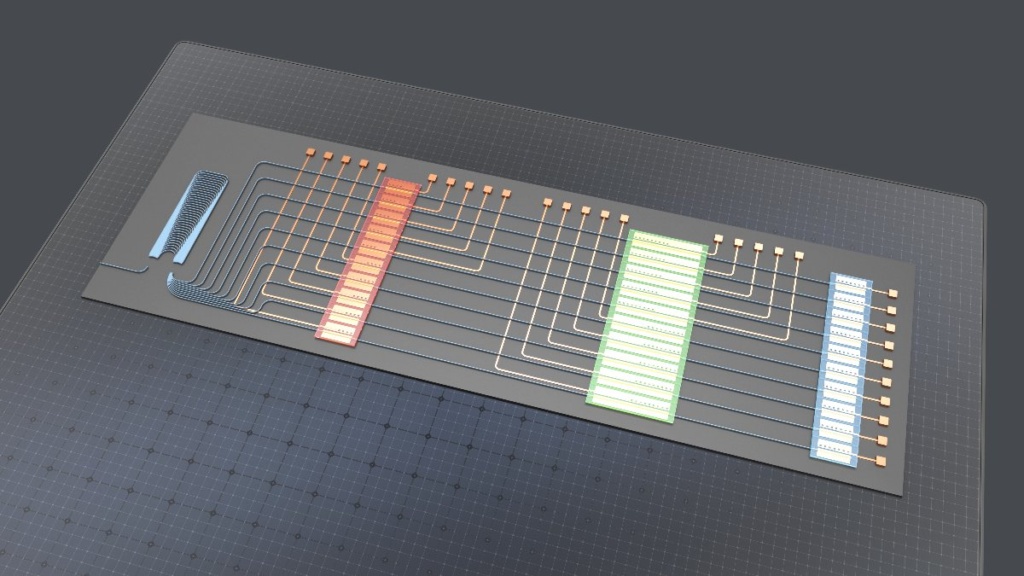

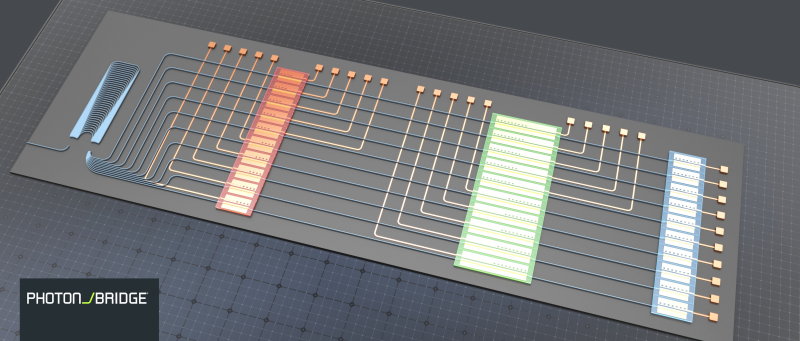

With a modular, de-integrated platform that separates active and passive components, Dutch startup Photon Bridge aims to simplify manufacturing, reduce costs and scale photonic integrated chip production for emerging AI and telecom applications.

Startup Photon Bridge is quietly laying the groundwork for a manufacturing revolution in integrated photonics. Led by CEO Paul Marchal, the Eindhoven-based firm is challenging the industry’s prevailing integration dogma to unlock manufacturability and scalability in next-gen photonic integrated chips (PICs).

Recognizing complexity challenges and yield limitations in conventional photonics integration, Photon Bridge’s technology originates from the scientific work of co-founder and CTO Rui Santos at Eindhoven University of Technology. “Rui saw that squeezing all functionality into a monolithic stack isn’t always optimal in terms of performance or manufacturability,” says Marchal.

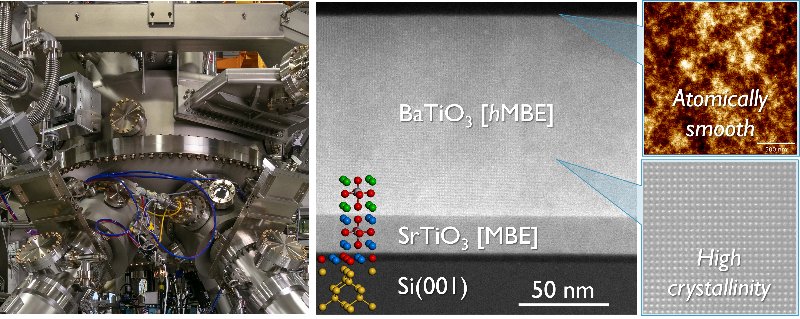

Photon Bridge’s approach is to separate active and passive photonic components. Active elements, such as lasers and amplifiers, are realized in III-V materials like indium phosphide (InP), while passive waveguides are fabricated in silicon. By using larger waveguides and keeping each subsystem in its optimal material platform, the company says it can improve manufacturing yield and reduce cost, while maintaining high optical performance.

This modular strategy is highly practical, Marchal points out. “Instead of trying to co-integrate everything, which adds complexity, we’re aligning pre-tested modules into a photonic system. Think of it as an optical PCB. You verify the components independently before placing them. That means higher intrinsic yield and simpler production.”

Brutal

The key enabler is Photon Bridge’s self-alignment technology. By designing waveguides and receiving grooves that mechanically lock into place, the company achieves sub-100nm optical alignment using standard pick-and-place tools to dramatically reduce packaging complexity and cost. “The system was initially developed for optical probing,” explains Marchal, “but we realized it could be used to create permanent, high-precision connections.”

The company’s flagship application is external laser sources for AI infrastructure, where demand for high-speed, multi-wavelength optical links is growing rapidly. “In this application, electrical interconnects are a bottleneck. Everyone’s looking to swap electrons for photons,” Marchal notes. “But co-packaged optics is going to need external laser sources with multiple precisely controlled wavelengths. That’s exactly where we shine.”

Photon Bridge says its architecture simplifies the creation of multi-wavelength light sources on a single fiber, a notoriously difficult challenge due to the precision required in modulator matching. Moreover, the company’s wider waveguides can handle 100x more optical power than typical submicron designs, a critical factor for long-reach and high-throughput applications.

While telecom is an important potential market too, Marchal sees AI data center optics as the real driver. “The price targets in AI are brutal, easily one or two orders of magnitude below telecom-grade components. Our de-integrated platform can hit those targets,” he says.

Tech push

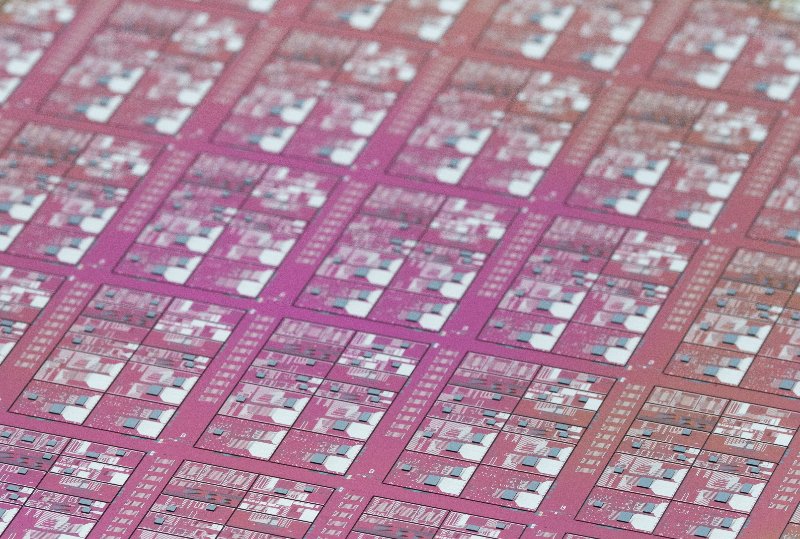

Photon Bridge is structured as a fully fabless operation, sourcing manufacturing from a diverse set of partners and focusing its internal efforts on design and system architecture. This keeps the company lean and scalable. “We want to be double or triple sourced for everything,” Marchal emphasizes. “That’s the only way to serve large-volume customers reliably.”

The company has completed a pilot production setup and is preparing prototype deliveries to its first customers – two major telecom firms. Marchal expects product qualification to take 12–18 months, with commercial rollout targeted within two years. In parallel, the team is scaling up, aiming to double its size to around 20 employees by the end of the year.

On the way to a projected seven- or eight-digit annual revenue, Photon Bridge has received crucial support from Photondelta, the Dutch national growth accelerator for integrated photonics. As a public-private partnership, Photondelta plays a key role in shaping and expanding the entire photonics ecosystem, from foundational R&D to industrial scale-up. “They don’t just finance individual companies; they help us build the networks and supply chain needed to take us to global markets.”

Despite the ambitious roadmap, Marchal remains grounded. “This has to fly within two years, or it doesn’t fly. We’re not doing a tech push, we’re building exactly what customers are asking for.”

Top image credit: Photon Bridge